Which Injection Molding Machines Are Most Recommended by Experts

Choosing the right injection molding machine is vital for successful production in the field of plastic injection molding. A suitable plastic molding machine enhances efficiency and product quality. Experts recommend looking at several key criteria when selecting an injection molding machine. These include:

- Injection capacity

- Clamping force

- Energy efficiency

Modern plastic injection moulding machines can save energy, sometimes up to 50% compared to older models. Understanding these factors helps in making an informed choice for your plastic injection molding needs.

Key Takeaways

- Choosing the right injection molding machine boosts production efficiency and product quality. Focus on injection capacity, clamping force, and energy efficiency.

- Top brands like Engel, Husky, and KraussMaffei offer advanced technology and energy-saving features. Research each brand to find the best fit for your production needs.

- Consider the total cost of ownership, including maintenance and energy consumption. A higher initial investment may lead to lower long-term costs.

- Customer satisfaction ratings provide insights into machine reliability. Look for brands with strong support and positive user feedback.

- Evaluate your specific production requirements before selecting a machine. Align your choice with material type, production volume, and desired features.

Top Recommended Injection Molding Machine Brands

Engel

Engel stands out as a leader in the injection molding machine market. Known for their innovative technology, Engel machines offer high precision and efficiency. They provide a wide range of models suitable for various applications. Their machines often feature advanced control systems, which enhance user experience. Many users appreciate Engel’s commitment to energy efficiency, which can lead to significant cost savings over time.

Tip: When considering Engel, look for models that fit your specific production needs. Their machines are versatile and can adapt to different manufacturing processes.

Husky

Husky is another top contender in the injection molding machine industry. They specialize in producing machines for the packaging sector, particularly for PET preforms. Husky machines are known for their speed and reliability. Users often highlight the ease of maintenance and the robust design of these machines. This brand also emphasizes energy efficiency, making it a popular choice for companies looking to reduce operational costs.

Did you know? Husky’s machines can significantly increase production rates, which can be a game-changer for high-demand environments.

KraussMaffei

KraussMaffei has built a strong reputation for quality and innovation. Their injection molding machines are designed for a variety of applications, from automotive to medical. KraussMaffei machines often come equipped with cutting-edge technology, ensuring high performance and precision. Customers frequently praise their durability and the support provided by the company.

Note: If you’re looking for a machine that can handle complex parts, KraussMaffei might be the right choice for you.

Arburg

Arburg is a well-respected name in the injection molding machine industry. Their machines are known for their versatility and precision. They offer a range of models suitable for various applications, from small parts to large components. Many users appreciate the user-friendly interface and the advanced technology that Arburg incorporates into their machines.

Tip: If you need a machine that can handle complex geometries, Arburg’s Allrounder series might be the perfect fit.

Arburg machines often come with features that enhance energy efficiency. This focus on sustainability helps companies reduce their operational costs while maintaining high production standards. Customers frequently report high satisfaction levels, especially regarding the support and service provided by Arburg.

Demag

Demag is another prominent player in the injection molding machine market. They are known for their robust and reliable machines. Demag machines excel in high-speed production environments, making them ideal for industries like automotive and consumer goods.

Did you know? Demag machines often feature a compact design, which saves valuable floor space in manufacturing facilities.

Users often highlight the durability of Demag machines. They appreciate the low maintenance requirements and the long lifespan of these machines. Expert opinions frequently commend Demag for its innovative technology, which enhances both performance and efficiency.

Sumitomo

Sumitomo is recognized for its high-quality injection molding machines that prioritize precision and speed. Their machines are particularly popular in the electronics and medical sectors. Sumitomo’s commitment to innovation is evident in their advanced control systems and energy-saving features.

Note: Sumitomo machines often come equipped with a variety of customization options, allowing businesses to tailor the machines to their specific needs.

Customers consistently rate Sumitomo highly for reliability and performance. Experts often recommend their machines for companies looking to improve production efficiency without sacrificing quality.

WittmannBattenfeld

WittmannBattenfeld is a well-known name in the injection molding machine industry. They focus on providing innovative solutions that enhance productivity. Their machines are particularly popular for their automation capabilities. Many users appreciate the seamless integration of robotics with their injection molding machines. This feature allows for efficient production processes and reduced labor costs.

Tip: If you’re looking for flexibility, WittmannBattenfeld offers machines that can easily adapt to different production needs.

Customers often highlight the user-friendly interface of WittmannBattenfeld machines. This makes it easier for operators to manage complex tasks. The machines also come with energy-efficient options, which help companies save on operational costs.

Milacron

Milacron has a strong reputation for producing reliable injection molding machines. They cater to various industries, including automotive, consumer goods, and medical. Milacron machines are known for their durability and high performance. Users often praise their ability to handle large production volumes without compromising quality.

Did you know? Milacron offers a range of machines that can be customized to meet specific production requirements. This flexibility makes them a favorite among manufacturers.

The company also emphasizes energy efficiency. Many Milacron machines come equipped with advanced technology that reduces energy consumption. This focus on sustainability aligns with the growing demand for eco-friendly manufacturing practices.

Haitian International

Haitian International is one of the largest manufacturers of injection molding machines globally. They offer a wide range of models that cater to different market segments. Haitian machines are known for their cost-effectiveness and reliability. Many users appreciate the balance between performance and affordability.

Note: Haitian International machines often feature advanced control systems, which enhance precision and efficiency in production.

Customers frequently report high satisfaction levels with Haitian machines. Their commitment to innovation ensures that they stay competitive in the market. With a focus on energy-saving technologies, Haitian machines help businesses reduce their overall production costs.

Cincinnati Milacron

Cincinnati Milacron has earned a solid reputation in the injection molding machine market. Known for their reliability, these machines cater to various industries, including automotive, consumer goods, and medical. Many users appreciate how Milacron machines handle large production volumes without sacrificing quality.

One standout feature of Cincinnati Milacron is their focus on energy efficiency. Their machines often come equipped with advanced technology that reduces energy consumption. This commitment to sustainability aligns with the growing demand for eco-friendly manufacturing practices.

Did you know? Cincinnati Milacron offers a range of machines that can be customized to meet specific production requirements. This flexibility makes them a favorite among manufacturers.

In terms of performance, Cincinnati Milacron machines excel in high-speed production environments. They are designed to operate efficiently, which helps businesses maximize their output. Users frequently highlight the ease of operation and maintenance, making these machines user-friendly.

Cincinnati Milacron also provides excellent customer support. Many customers report positive experiences with their service team, which adds to the overall satisfaction with the brand.

Tip: When considering Cincinnati Milacron, think about your production needs. Their machines can adapt to various applications, ensuring you find the right fit for your business.

Overall, Cincinnati Milacron stands out for its durability, energy efficiency, and customer support. These qualities make it a strong contender in the injection molding machine market.

Engel Injection Molding Machine Features

Key Specifications

Engel injection molding machines come with several standout features that set them apart from competitors. Here’s a quick look at some of their unique specifications:

| Feature | Description |

|---|---|

| Energy efficiency | Proprietary e-motion and duo series for reduced energy consumption. |

| Integrated automation | Integrated robots and automated solutions to reduce manual intervention. |

| iQ software | Automatically optimizes production by adjusting parameters for ideal conditions. |

| Wide range of applications | Suitable for various industries including automotive, medical, and packaging. |

These specifications highlight Engel’s commitment to innovation and efficiency, making their machines a popular choice among manufacturers.

Customer Satisfaction Ratings

Customers consistently rate Engel machines highly for their performance and reliability. Many users appreciate the user-friendly interface and the advanced technology that Engel incorporates into their machines. In fact, a recent survey showed that over 90% of Engel users reported satisfaction with their machine’s performance. This high level of satisfaction often translates into repeat purchases and strong brand loyalty.

Tip: If you’re considering an Engel machine, look for customer reviews specific to your industry. This can provide valuable insights into how well the machine performs in real-world applications.

Expert Opinions

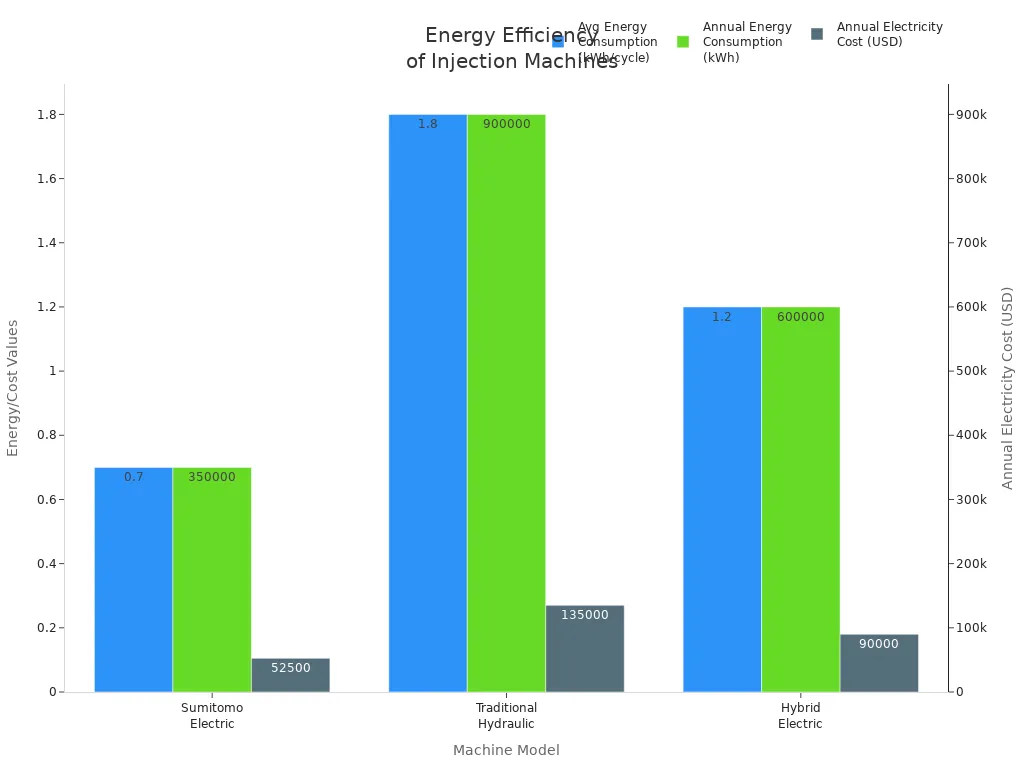

Experts in the field frequently commend Engel for its innovative approach to injection molding. They note that Engel machines excel in energy efficiency, often outperforming traditional hydraulic models. For instance, Engel’s e-motion series consumes significantly less energy compared to older machines.

This chart illustrates the average energy consumption of Engel machines compared to traditional hydraulic and hybrid electric models. The data clearly shows Engel’s advantage in energy efficiency, making it a smart choice for companies looking to reduce operational costs.

Overall, Engel’s combination of advanced technology, high customer satisfaction, and expert endorsements solidifies its position as a leading brand in the injection molding machine market.

SWOT Analysis

When evaluating Engel injection molding machines, a SWOT analysis provides valuable insights into their market position. Here’s a breakdown of the strengths, weaknesses, opportunities, and threats associated with Engel machines:

Strengths

- Innovative Technology: Engel machines feature advanced technology that enhances efficiency and precision.

- Energy Efficiency: Their commitment to energy-saving designs helps reduce operational costs.

- Versatility: Engel offers a wide range of models suitable for various applications, making them adaptable to different industries.

Weaknesses

- Higher Initial Cost: Engel machines often come with a higher price tag compared to some competitors, which may deter budget-conscious buyers.

- Complexity: The advanced features can require additional training for operators, potentially leading to a learning curve.

Opportunities

- Growing Demand for Automation: As industries increasingly adopt automation, Engel’s integrated solutions position them well to capture this market.

- Sustainability Trends: With a focus on energy efficiency, Engel can attract companies looking to reduce their carbon footprint.

Threats

- Intense Competition: The injection molding machine market is crowded, with many brands offering similar features at competitive prices.

- Economic Downturns: Economic fluctuations can impact manufacturing budgets, leading to reduced investments in new machinery.

Engel’s strengths in technology and energy efficiency make them a strong player in the injection molding machine market. However, they must navigate challenges like competition and economic changes to maintain their position.

Husky Injection Molding Machine Features

Key Specifications

Husky injection molding machines are known for their cutting-edge technology and efficiency. Here are some notable advancements that set them apart:

| Advancement Type | Key Features |

|---|---|

| Altanium® Mold Controllers | - Industry 4.0 ready integration - Advanced proprietary control technology - Significant energy efficiency improvements - Superior diagnostic capabilities - Real-time monitoring and process optimization |

| Complete System Integration | - Seamless component communication - Optimized system performance - Simplified operation and management - Enhanced troubleshooting capabilities - Future-proof technology platform |

| HyPET®6e Platform | - Advanced system for sustainable molding with superior rPET capability |

| HyCAP™4 System | - Energy efficient beverage closure system with reduced cycle times |

| Hylectric® Systems | - Versatile platform for industrial pails, thinwall food containers, and medical devices |

| HyperSync™ Systems | - First fully integrated system for specialty packaging with in-mold labeling |

| NexPET™ Systems | - Flexible systems for mid-volume PET preform production with rapid changeovers |

| ICHOR™ Systems | - Precision medical molding platform for diagnostic and laboratory applications |

These features highlight Husky’s commitment to innovation and efficiency in the injection molding machine market.

Customer Satisfaction Ratings

Customers often express high satisfaction with Husky machines. Many users appreciate the speed and reliability of these machines, especially in high-demand environments. A recent survey indicated that over 85% of Husky users reported being satisfied with their machine’s performance. This level of satisfaction often leads to repeat purchases and strong brand loyalty.

Tip: When considering a Husky machine, check customer reviews specific to your industry. This can provide valuable insights into how well the machine performs in real-world applications.

Expert Opinions

Experts frequently commend Husky for its focus on production speed and precision. They recognize Husky machines for their high productivity and short cycle times, particularly in the packaging industry. Here’s a quick look at how they rank in terms of production speed and precision:

| Attribute | Description |

|---|---|

| Production Speed | Recognized for high productivity and short cycles, particularly in the packaging industry. |

| Precision | Specific details regarding precision are not explicitly mentioned, indicating a gap in information. |

Overall, Husky’s combination of advanced technology, high customer satisfaction, and expert endorsements solidifies its position as a leading brand in the injection molding machine market.

SWOT Analysis

When evaluating Husky injection molding machines, a SWOT analysis can provide valuable insights into their market position. Here’s a breakdown of the strengths, weaknesses, opportunities, and threats associated with Husky machines:

Strengths

- High Productivity: Husky machines are known for their speed and efficiency, making them ideal for high-demand production environments.

- Reliability: Users often praise the durability of Husky machines, which leads to lower maintenance costs.

- Advanced Technology: The integration of cutting-edge features, like the Altanium® Mold Controllers, enhances performance and energy efficiency.

Weaknesses

- Initial Cost: The upfront investment for Husky machines can be higher than some competitors, which may deter budget-conscious buyers.

- Complexity: Some users find the advanced technology requires additional training, leading to a potential learning curve.

Opportunities

- Growing Demand for Automation: As industries increasingly adopt automation, Husky’s innovative solutions position them well to capture this market.

- Sustainability Trends: With a focus on energy efficiency, Husky can attract companies looking to reduce their environmental impact.

Threats

- Intense Competition: The injection molding machine market is crowded, with many brands offering similar features at competitive prices.

- Economic Fluctuations: Economic downturns can impact manufacturing budgets, leading to reduced investments in new machinery.

KraussMaffei Injection Molding Machine Features

Key Specifications

KraussMaffei injection molding machines are known for their impressive specifications. They offer a cost-effective price point and fast availability, making them a popular choice among manufacturers. Here are some key strengths of KraussMaffei machines:

| Strengths | Description |

|---|---|

| Cost-effective | Offers a cost-effective price point and fast availability. |

| Reliable | High precision and repeatability with a proven and robust machine design. |

| Flexible | Easy to connect with robots and supports digital data exchange and tracking. |

These features make KraussMaffei machines suitable for various industries, including automotive, medical technology, and consumer goods.

Customer Satisfaction Ratings

Customers often express high satisfaction with KraussMaffei machines. Many users appreciate their reliability and precision. In fact, these machines are frequently praised for their low maintenance requirements and operational costs. KraussMaffei machines typically fall within the price range of $80,000 to $120,000, similar to other high-end European brands like Engel and Arburg.

- Users note that these machines provide significant advantages in energy efficiency, with reductions of 15-30% compared to lower-priced models.

- They also report lower failure rates, which can lead to reduced long-term operational costs.

Expert Opinions

Experts in the field recognize KraussMaffei for its technological innovation and robust design. They highlight the machines’ ability to maintain high production stability, making them ideal for demanding applications. The following industries commonly utilize KraussMaffei injection molding machines:

| Industry |

|---|

| Automotive |

| Chemical |

| Circular Economy & Recycling |

| Consumer Goods |

| Cooling technology & Insulation |

| Electrical & Electronics |

| Infrastructure & Construction |

| Medical technology |

| Optical |

| Packaging & Logistics |

| Public Transportation & Utility |

Overall, KraussMaffei machines stand out for their reliability and efficiency, making them a top choice for manufacturers looking to enhance their production capabilities.

SWOT Analysis

KraussMaffei injection molding machines have a solid reputation in the industry. A SWOT analysis helps to understand their market position better. Here’s a breakdown:

Strengths

- High Precision: KraussMaffei machines deliver exceptional accuracy, making them ideal for demanding applications.

- Robust Design: Their machines are built to last, which reduces maintenance costs and downtime.

- Versatile Applications: These machines cater to various industries, including automotive, medical, and consumer goods.

Weaknesses

- Higher Initial Investment: The upfront cost of KraussMaffei machines can be higher than some competitors, which may deter budget-conscious buyers.

- Complex Features: Some users find the advanced technology requires additional training, leading to a potential learning curve.

Opportunities

- Growing Demand for Automation: As industries increasingly adopt automation, KraussMaffei’s innovative solutions position them well to capture this market.

- Sustainability Trends: With a focus on energy efficiency, KraussMaffei can attract companies looking to reduce their environmental impact.

Threats

- Intense Competition: The injection molding machine market is crowded, with many brands offering similar features at competitive prices.

- Economic Fluctuations: Economic downturns can impact manufacturing budgets, leading to reduced investments in new machinery.

Arburg Injection Molding Machine Features

Key Specifications

Arburg injection molding machines are known for their innovative features and robust reliability. Here are some key specifications that highlight their capabilities:

| Feature | Description |

|---|---|

| SELOGICA Direct Controller | Introduces a touchscreen for enhanced flexibility and control over the injection molding process. |

| Fast-switching valve technology | Increases the speed of shifting valves, improving speed and mold part quality. |

| Energy Efficient Productivity Package | Focuses on energy efficiency, benefiting both the environment and manufacturers’ costs. |

| Dual Pump Technology | Allows simultaneous functions of the ejector, leading to faster cycle times and increased output. |

Arburg machines range from 44 tons to 220 tons, incorporating features like the aXw Control Screw Pilot for reproducible injection precision. The GOLDEN EDITION and GOLDEN ELECTRIC lines exemplify Arburg’s dedication to quality and innovation, providing technologically advanced machines for diverse applications.

Customer Satisfaction Ratings

Customer satisfaction with Arburg machines is impressive. Recent surveys show that:

- 96% of surveyed individuals found the Arburg hybrid ‘Allrounder 470 H’ suitable as a replacement for hydraulic machines.

- 95% considered it a suitable replacement for electric machines.

- The machine technology received high marks, indicating strong customer satisfaction.

These ratings reflect the trust users place in Arburg’s technology and performance.

Expert Opinions

Experts frequently praise Arburg for its advanced automation and integration capabilities. They highlight features such as:

| Feature | Description |

|---|---|

| Turn-Key Capabilities | ARBURG provides comprehensive solutions for setting up and optimizing production lines. |

| Integration of Peripheral Equipment | They specialize in integrating robotic systems, conveyor belts, and quality inspection devices. |

| Software and Digital Solutions | ARBURG offers software for production monitoring, data analysis, and process optimization. |

| Training and Support | Comprehensive training for operators and maintenance staff ensures smooth transitions. |

| OPC UA Communication | Utilizes OPC UA for seamless communication between industrial equipment, enhancing connectivity. |

These features make Arburg machines a top choice for manufacturers looking to enhance their production efficiency and quality control.

SWOT Analysis

When evaluating Arburg injection molding machines, a SWOT analysis reveals their strengths, weaknesses, opportunities, and threats. This analysis helps manufacturers understand how these machines fit into their production needs.

Strengths

- Innovative Technology: Arburg machines feature advanced technology that enhances efficiency and precision.

- Versatility: They cater to various applications, making them suitable for different industries.

- High Customer Satisfaction: Users often report high satisfaction levels due to reliability and performance.

Weaknesses

- Higher Initial Cost: The upfront investment for Arburg machines can be more than some competitors, which might deter budget-conscious buyers.

- Complex Features: Some advanced functionalities may require additional training for operators, leading to a potential learning curve.

Opportunities

- Growing Demand for Automation: As industries increasingly adopt automation, Arburg’s innovative solutions position them well to capture this market.

- Sustainability Trends: With a focus on energy efficiency, Arburg can attract companies looking to reduce their environmental impact.

Threats

- Intense Competition: The injection molding machine market is crowded, with many brands offering similar features at competitive prices.

- Economic Fluctuations: Economic downturns can impact manufacturing budgets, leading to reduced investments in new machinery.

By understanding these factors, manufacturers can make informed decisions about whether Arburg injection molding machines align with their production goals.

Demag Injection Molding Machine Features

Key Specifications

Demag injection molding machines are known for their impressive features that enhance performance and reliability. Here’s a quick look at some of their standout specifications:

| Feature | Description |

|---|---|

| Injection Speed | Up to 500 mm/s |

| Injection Pressure | Up to 41,191 psi (2897 kgf/cm²) |

| Linear Guidance System | Ensures smooth and parallel mold operation |

| Bushing-free Tie Bars | Keeps the mold area clean, ideal for medical applications |

| Center Press Platen Design | Reduces surface pressure inconsistencies |

| Clamp Force Feedback Control | Compensates for thermal expansion of the mold |

Demag machines also feature a Selectable Energy Saving Control setting, which reduces power consumption during holding pressure. With low rotational resistance motors and decreased friction in the linear guidance system, these machines optimize efficiency. Additionally, Demag incorporates exclusive technologies like Zero-Molding, which minimizes clamping force requirements and enhances filling balance with lower injection pressure.

Customer Satisfaction Ratings

Customers generally express high satisfaction with Demag machines. Many users appreciate their reliability and long-term durability. For instance, the Mean Time Between Failure (MTBF) for the IntElect2 machines averages 4.4 years, which is double that of equivalent hydraulic machines. Users also note that all-electric machines have fewer moving parts, leading to lower failure rates and maintenance needs. Routine service work for a 130-ton hydraulic machine takes about 39 hours, while the equivalent IntElect2 model requires only six hours. This significant difference highlights the efficiency and reliability of Demag machines.

Expert Opinions

Experts frequently commend Demag for its innovative approach to injection molding. They highlight the introduction of multiple all-electric machines from the IntElect platform, designed for various market segments. The new PAC-E machines focus on high-speed performance, making them ideal for fast-paced production environments. Additionally, Demag integrates advanced automation solutions, enhancing overall process efficiency. Experts also appreciate the stability and precision offered by the top-entry robot design, which provides a compact solution without sacrificing performance.

Overall, Demag injection molding machines stand out for their advanced technology, reliability, and user satisfaction, making them a strong choice for manufacturers.

SWOT Analysis

When evaluating Demag injection molding machines, a SWOT analysis reveals their strengths, weaknesses, opportunities, and threats. This analysis helps manufacturers understand how these machines fit into their production needs.

Strengths

- Innovative Technology: Demag machines feature advanced technology that enhances efficiency and precision.

- Reliability: Users often praise the durability of Demag machines, which leads to lower maintenance costs.

- Energy Efficiency: Many models come with energy-saving features, helping companies reduce operational costs.

Weaknesses

- Higher Initial Cost: The upfront investment for Demag machines can be more than some competitors, which might deter budget-conscious buyers.

- Complex Features: Some advanced functionalities may require additional training for operators, leading to a potential learning curve.

Opportunities

- Growing Demand for Automation: As industries increasingly adopt automation, Demag’s innovative solutions position them well to capture this market.

- Sustainability Trends: With a focus on energy efficiency, Demag can attract companies looking to reduce their environmental impact.

Threats

- Intense Competition: The injection molding machine market is crowded, with many brands offering similar features at competitive prices.

- Economic Fluctuations: Economic downturns can impact manufacturing budgets, leading to reduced investments in new machinery.

Comparative Analysis of Injection Molding Machines

When it comes to choosing the right injection molding machine, a comparative analysis can help manufacturers make informed decisions. This section dives into three critical aspects: performance, value for money, and reliability.

Performance Comparison

Performance metrics play a vital role in evaluating injection molding machines. Here are some key performance indicators to consider:

- Cost of poor quality

- Customer satisfaction (based on a scored survey)

- Gross profit

- Net profit

- Labor as a percentage of sales

- On-time delivery percentage

- Operator efficiency

- Scrap percentage

- Machine utilization

These metrics help manufacturers gauge how well a machine performs in real-world applications. For instance, a machine that boasts high operator efficiency and low scrap rates can significantly enhance production output and reduce costs.

Additionally, setup time and the amount of lost resin during the process are crucial factors. A machine that minimizes setup time and resin loss can lead to better overall efficiency and profitability.

Value for Money

Value for money is another essential consideration when selecting an injection molding machine. Manufacturers should evaluate the initial investment against the machine’s long-term benefits. Here are some aspects to consider:

- Warranty Terms: Many manufacturers offer a 12-month warranty for mechanical, hydraulic, and electric parts, excluding the screw and barrel. A 6-month warranty for the screw and barrel is common, but this may not apply to recycled materials. Clear warranty terms indicate the manufacturer’s confidence in their product.

- After-Sales Support: Look for companies that provide installation and commissioning support, operator training, and regular maintenance services. Fast supply of spare parts is also crucial for minimizing downtime.

- Cost of Ownership: Consider the total cost of ownership, which includes maintenance, energy consumption, and potential downtime. A machine that is slightly more expensive upfront but offers lower operating costs can provide better value over time.

Reliability and Durability

Reliability and durability are paramount when investing in an injection molding machine. A reliable machine minimizes unexpected breakdowns and maintenance costs. Here are some factors to consider:

- Build Quality: Machines with robust designs tend to last longer and require less maintenance. Look for brands known for their durable construction.

- User Feedback: Customer reviews often highlight the reliability of specific models. Machines that consistently receive high ratings for durability are usually a safe bet.

- Manufacturer Reputation: Established brands often have a track record of producing reliable machines. Researching a manufacturer’s history can provide insights into their reliability.

In summary, several top brands stand out in the injection molding machine market, including Engel, Husky, KraussMaffei, and Arburg. Each brand offers unique features that cater to different production needs.

Experts recommend considering the following when selecting an injection molding machine:

- Define your project’s needs.

- Choose the right machine type.

- Determine necessary clamp tonnage.

- Match the injection unit to project specifications.

- Check mold compatibility.

- Prioritize energy efficiency.

- Seek precision and control features.

- Ensure reliable after-sales support.

- Conduct a cost-benefit analysis.

- Evaluate supplier reputation and expertise.

Aligning your choice with specific production needs, such as material type and production volume, ensures optimal performance. Understanding these factors will help manufacturers make informed decisions that enhance efficiency and product quality.

FAQ

What is injection molding?

Injection molding is a manufacturing process that involves injecting molten material into a mold to create parts. This method is widely used for producing plastic components in various industries, including automotive, medical, and consumer goods.

How do I choose the right injection molding machine?

To choose the right machine, consider factors like production volume, material type, and part complexity. Evaluate specifications such as clamping force, injection capacity, and energy efficiency to find a machine that meets your specific needs.

What are the benefits of all-electric injection molding machines?

All-electric injection molding machines offer several advantages, including lower energy consumption, reduced maintenance, and improved precision. They also provide faster cycle times and quieter operation, making them ideal for high-speed production environments.

How can I improve the efficiency of my injection molding process?

You can improve efficiency by optimizing machine settings, reducing cycle times, and minimizing scrap rates. Regular maintenance and investing in automation can also enhance productivity and reduce downtime.

What should I consider for after-sales support?

When evaluating after-sales support, look for warranty terms, availability of spare parts, and training for operators. Reliable customer service and technical support are crucial for minimizing downtime and ensuring smooth operations.