- Home

- News

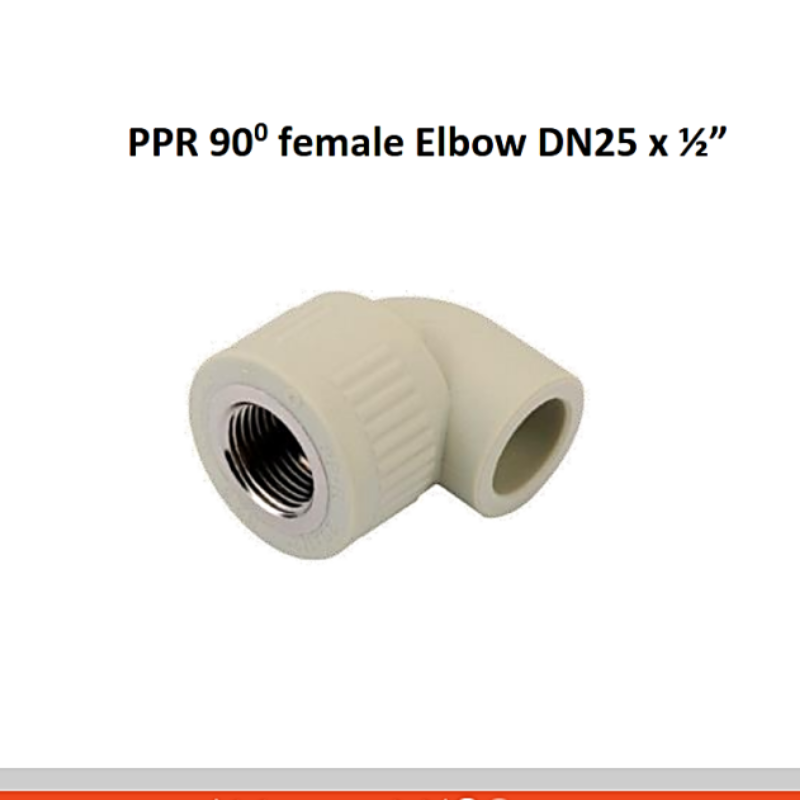

- A Benchmark Success Case in the Pipe Fitting Industry: Automated Solution for PPR Elbow Pipe Hardware Inserts & Trimmed Scrap

A Benchmark Success Case in the Pipe Fitting Industry: Automated Solution for PPR Elbow Pipe Hardware Inserts & Trimmed Scrap

In the competitive landscape of the pipe fitting industry, we are thrilled to share another milestone achievement—a tailor-made automation solution that has become a game-changer for one of our benchmark clients, specifically designed for PPR elbow pipe hardware inserts and trimmed scrap processing. This solution has not only optimized the client’s production work-flow but also delivered measurable efficiency gains that redefine operational standards in the sector.

This cutting-edge solution revolves around two core custom components: an open-type bull head robot arm engineered for high compatibility (supporting 8-20mm PPR elbow pipe specifications, covering over 90% of the client’s mainstream product models) and a customized robotic end arm tool built for precision (positioning accuracy within ±0.2mm, ensuring zero misalignment in hardware embedding). Together, they break through traditional production limits by enabling 16-cavity automation for PPR elbow pipe insert trimming—this means the system can process 16 PPR elbow pipes in a single production cycle, compared to just 2-3 pieces per cycle with the client’s previous semi-automated setup, marking a 700% increase in unit-cycle output. What makes this solution comprehensive and practical? It integrates three key production steps seamlessly, with each link delivering tangible performance improvements:

- Robotic Hardware Insertion: The customized robotic end EOAT ensures accurate and stable embedding of hardware into PPR elbow pipes. Before automation, manual insertion led to a 3.2% defect rate due to human error; now, the defect rate has plummeted to 0.15%, while the insertion speed has risen from 12 pieces per minute (manual) to 48 pieces per minute (automated).

- Hardware Feeding Automation: The system is equipped with an intelligent vibration feeding tray that can hold up to 5,000 hardware pieces at once, eliminating the need for manual material replenishment every 30 minutes. It maintains a continuous feeding speed of 60 pieces per minute, matching the robotic insertion rhythm perfectly and reducing material waste caused by manual handling from 2.1% to 0.3%.

- Robotic Part Retrieval & Scrap Trimming: After the molding process, the robot not only retrieves the finished PPR elbow pipes but also trims the excess scrap in one go. This dual-function step cuts down the total processing time per piece from 15 seconds (manual retrieval + separate trimming) to 4 seconds (integrated automated operation). Over an 8-hour shift, this saves 128 working hours of labor per month for the client.

Currently, this automation solution has been fully deployed in the client’s factory for 3 months, operating with a stable 98.5% equipment up time (excluding scheduled maintenance). It has successfully transformed the client’s production mode: the number of workers required for the PPR elbow production line has decreased from 8 to 2 (responsible for supervision and maintenance only), while the daily output has jumped from 1,800 pieces to 12,600 pieces—a 600% increase in daily production capacity.

For pipe fitting manufacturers seeking to upgrade automation, this case sets a clear and explicable benchmark with quantifiable results.

#PPRFittingAutomation #PipeFittingIndustrySolution #IndustrialAutomationCase #SmartManufacturingForPipes #CustomAutomationEquipment