What sets a plastic granulator machine apart from a plastic shredder?

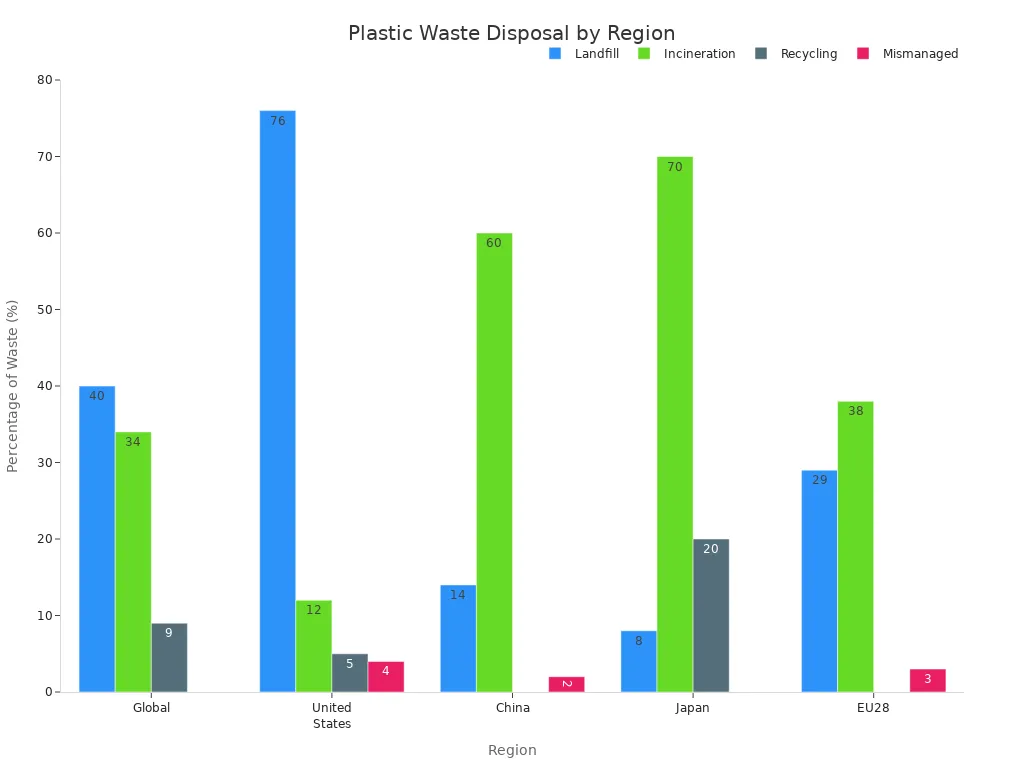

Plastic waste keeps growing, with about 400 million tonnes produced globally in 2022. Only 9% gets recycled, as shown below.

Choosing between a Plastic Granulator Machine and a Plastic Shredder changes how Plastic Recycling Machines work.

- Granulator makes small, uniform pieces for easy recycling.

- Plastic Shredder handles bulky scrap and tough materials.

Picking the right machine boosts efficiency.

| Statistic / Region | Value / Description |

|---|---|

| Global plastic waste generation | ~400 million tonnes in 2022 |

| Global recycling rate | Approximately 9% (stagnant) |

| United States recycling rate | 5% recycled, 76% landfilled, 12% incinerated, 4% mismanaged |

| Japan incineration rate | 70%, landfill 8%, recycling ~20% |

Key Takeaways

- Plastic shredders break down large, tough plastic waste into big chunks, making them ideal for handling bulky or mixed materials at the start of recycling.

- Plastic granulator machines slice plastic into small, uniform granules, perfect for clean, sorted scraps and ready for reuse in molding or extrusion.

- Choosing the right machine depends on your plastic type and size: use shredders for big, heavy items and granulators for refining smaller pieces into consistent granules.

Plastic Granulator Machine vs. Plastic Shredder: Definitions and Working Principles

What Is a Plastic Granulator Machine?

A Plastic Granulator Machine is a device that cuts plastic waste into small, uniform granules. These machines help recycling centers and factories turn scrap plastic into pieces ready for reuse. They work best with items like sprues, runners, film edges, and start-up scrap. Most granulators use a single rotor with sharp knives to slice the plastic.

Granulators are popular for processing common plastics such as polyethylene, polypropylene, and polystyrene.

How Does a Plastic Granulator Machine Work?

The process starts when workers feed plastic into the hopper. Inside the cutting chamber, rotating blades slice the material against fixed blades. A screen or mesh filters the granules, letting only the right size pass through. Larger pieces go back for more cutting. The motor powers the blades and controls the speed. The finished granules collect in a bin, ready for molding or extrusion.

- Main components:

- Hopper

- Cutting chamber

- Rotating and fixed blades

- Screen or mesh

- Motor and drive system

- Collection bin

What Is a Plastic Shredder?

A plastic shredder is a machine built to break down bulky, tough plastic waste. Shredders handle items like car bumpers, drums, and pipes. They use slow speed and high torque to tear plastics into large, uneven chunks. Shredders come in different types, such as single-shaft, double-shaft, and four-shaft models.

| Shredder Type | Best Suited Plastic Waste Types |

|---|---|

| Grinder | Hard and bulky plastics |

| Chippers | Rigid plastics; large items like crates, pallets |

| Shear Shredders | Bulky, thick plastics; drums, pipes |

| All-Purpose Shredders | Mixed plastic waste |

How Does a Plastic Shredder Work?

Plastic shredders use powerful blades mounted on shafts. The machine grabs and pulls the plastic, then tears it apart. The output is larger and less uniform than granulator granules. Shredders often serve as the first step in recycling, making big pieces small enough for further processing.

Shredders operate quietly and include safety features like automatic reversing and torque limiters.

Comparing Plastic Granulator Machine and Plastic Shredder: Key Differences

Operation and Cutting Mechanism

The way these two machines cut plastic is very different. Granulators use sharp, fast-moving blades that slice plastic into small pieces. They work at high speeds, usually between 400 and 800 rpm, and use low torque. Their blades are thin and made for precision. This design helps them cut clean, sorted plastic scrap into uniform granules.

Shredders, on the other hand, use thick, strong blades that move slowly but with a lot of force. They usually run at 10 to 130 rpm. Their blades have hooks or teeth and can handle bulky or mixed plastic waste. Shredders tear and break down tough materials, making them great for the first step in recycling.

Here’s a quick look at how their blades compare:

| Feature | Plastic Granulator Blades | Plastic Shredder Blades |

|---|---|---|

| Operation Speed | High-speed (400–800 rpm) | Low-speed (10–130 rpm) |

| Cutting Mechanism | Shearing against a stationary bed knife | Tearing with hooked or toothed blades on multiple shafts |

| Blade Shape | Sharp, precision-engineered knives | Thicker, more robust cutters |

| Material Hardness | High-hardness steels like D2 or SKD11 | Impact-resistant, designed for durability |

| Application | Clean, pre-sorted plastics (e.g., injection-molded parts) | Bulky, contaminated, or rigid plastic waste |

| Purpose | Produces small, uniform granules for reuse | Breaks down large or tough materials into chunks |

Tip: Granulators are best for clean, sorted plastic. Shredders are better for bulky, mixed, or dirty plastic.

Output Size and Consistency

Granulators and shredders produce very different results. Granulators make small, even pieces. Most granules are about 10mm by 10mm, and the size can be adjusted by changing the screen. The standard size is around 12mm, but it can range from 8mm to 20mm. This uniform size makes the granules easy to reuse in new products.

Shredders create bigger, rougher pieces. The chunks are usually around 40mm and can vary a lot in size and shape. These pieces often need more processing before they can be used again. Granulators give a more consistent output, while shredders focus on breaking down large items quickly.

- Granulators: Small, uniform granules (about 10mm x 10mm)

- Shredders: Large, uneven chunks (about 40mm), less consistent

Material Handling Capabilities

Shredders can handle almost anything you throw at them. They work with thick, bulky, or oddly shaped plastic. The maximum input size depends on the feed port and the power of the motor. Some shredders can take pieces as big as 1000×500 mm. They can process plastics with thicknesses from about 0.7 mm up to 12 mm or more, depending on the machine.

Granulators need smaller, cleaner pieces. They work best with items like sprues, runners, bottles, and film edges. Large or very thick items must be broken down before going into a granulator. If the plastic is too thin, like film, it might slip through a shredder’s blades instead of being cut.

Note: Shredders are the go-to for big, tough jobs. Granulators are perfect for refining smaller, cleaner scraps.

Typical Applications and Use Cases

Granulators and shredders both play important roles in recycling, but they fit into different parts of the process.

Plastic Granulator Machine is common in:

- Injection molding plants (reusing sprues, runners, and defective parts)

- Blow molding units (recycling bottles and containers)

- Extrusion units (recovering trimmings and off-spec profiles)

- Plastic dana making units (making granules for pelletizing)

- Plastic recycling plants (turning post-consumer plastic into raw material)

- Packaging industry (reprocessing film scraps and sheet waste)

| Industrial Sector | Common Applications of Plastic Granulator Machines |

|---|---|

| Injection Molding Plants | Reuse of sprues, runners, and defective molded parts |

| Blow Molding Units | Recycling bottles, drums, and hollow containers |

| Extrusion Units | Recovery of trimmings and off-spec profiles or sheets |

| Plastic Dana Making Units | Feeding system to generate granules for pelletizing |

| Plastic Recycling Plants | Conversion of post-consumer plastic into secondary raw materials |

| Packaging Industry | Reprocessing film scraps, bubble wrap, and sheet waste |

Shredders are used in:

- Recycling centers (start-up purges, crates, pallets, pipes, containers)

- Manufacturing facilities (handling molded parts and post-consumer waste)

- Consumer waste management (PET bottles, packaging)

- Automotive and electronics industries (processing tough plastics and mixed waste)

- Medical and food processing (safe disposal of plastic waste)

- Agricultural film recycling

- Shredders handle a wide range of plastics, rubber, fibers, and even tough materials like Kevlar and carbon.

- They are also used in tire recycling, hazardous waste, and scrap metal processing.

Shredders start the recycling process by breaking down big items. Granulators finish the job by making small, reusable granules.

Side-by-Side Comparison Table

Here’s a table to help you see the main differences at a glance:

| Performance Metric | Plastic Granulator Machine | Plastic Shredder |

|---|---|---|

| Cutting Mechanism | High-speed, precision slicing | Low-speed, high-torque tearing |

| Output Size | Small, uniform granules (8–20mm) | Large, irregular chunks (up to 40mm+) |

| Material Handling | Clean, pre-sorted, smaller pieces | Bulky, mixed, or contaminated plastics |

| Typical Applications | Injection molding, extrusion, packaging | Recycling centers, waste management, auto |

| Maintenance Needs | Lower, easy-access parts | Higher, regular blade replacement |

| Throughput Capacity | Moderate (200–300 kg/hour) | High (up to 2 tons/hour) |

| Operational Cost | Lower energy and maintenance | Higher labor and part costs |

| Integration | Standalone or central granulators | Standalone or integrated with granulators |

Choosing the right machine depends on your material type, desired output, and where you fit in the recycling process.

Choosing Between a Plastic Granulator Machine and a Plastic Shredder

Material Type and Size Considerations

Choosing the right machine starts with looking at the type and size of plastic waste. Shredders work best for large, bulky items like drums, pipes, or car bumpers. They break these down into smaller shreds, making them easier to handle. Granulators take over when the plastic is already in smaller pieces or after shredding. They refine the material into uniform granules. The table below shows how each machine fits different needs:

| Factor | Plastic Granulator Machine | Plastic Shredder |

|---|---|---|

| Scrap Size & Feed Rate | Light to medium scrap | Large, bulky scrap |

| Output Size & Purpose | Uniform granules | Coarse shreds |

| Operation Characteristics | High-RPM, low-torque | High-torque, low-RPM |

| Limitations | Struggles with heavy parts | Not ideal for light scrap |

Tip: For engineering plastics in rod or plate form, a shredder should go first, followed by a granulator for best results.

Desired Output and End Use

The final use of recycled plastic guides the choice between machines. Granulators produce small, even granules, perfect for injection molding, extrusion, or blow molding. Shredders create larger, rough pieces that often need more processing. The table below highlights recommended output sizes for different uses:

| End Use / Process | Recommended Output Size (mm) | Purpose / Benefit |

|---|---|---|

| Injection molding, extrusion | 6.35 – 9.5 | Direct reuse in production |

| WEEE plastic flakes sorting | 10 – 20 | Improves sorting and recyclability |

A step-by-step approach helps match the machine to the job:

- Check if the plastic is flexible or rigid.

- Look at the size and shape.

- Think about contamination.

- Match the machine to the material and output needs.

- Consider cost and space.

Operational Factors: Speed, Maintenance, and Cost

Speed, upkeep, and cost matter when picking a machine. Granulators run at higher speeds and make finer particles. They need regular blade sharpening but use less power. Shredders work slower, use more torque, and handle tough jobs. They cost more to run and maintain, especially for heavy-duty models. The table below compares these factors:

| Feature | Plastic Granulator Machine | Plastic Shredder |

|---|---|---|

| Operational Speed | High | Low |

| Output Size | Small, uniform | Large, varied |

| Maintenance | Regular blade care | Frequent blade replacement |

| Cost | Lower | Higher |

Note: Facilities with lots of bulky waste may prefer shredders, while those needing fine, reusable granules often choose granulators.

Choosing the right machine matters. Shredders break down bulky plastics first, while granulators create small, uniform pieces for reuse. Both play key roles in recycling. For quick reference, check this table for expert tips on picking the best fit for your scrap and process:

| Factor | Granulator | Shredder |

|---|---|---|

| Speed | High | Low |

| Scrap Volume | Any size | Best for large amounts |

| Output Size | Small, uniform | Large, rough |

FAQ

What plastics can a granulator machine process?

A granulator handles clean, sorted plastics like bottles, sprues, and film edges. It works best with materials such as polyethylene, polypropylene, and polystyrene.

Can a shredder and granulator work together?

Yes! Many recycling plants use a shredder first for big items. Then, they use a granulator to make small, uniform granules.

How often should operators maintain these machines?

Operators should check blades weekly. They should sharpen or replace them as needed. Regular cleaning keeps both machines running smoothly and safely.