How will you determine the best plastic molding machine for your future projects?

Selecting the optimal Plastic Molding Machine is crucial for project success and future business growth. A thorough evaluation of project-specific needs and machine capabilities ensures strategic investment. Consider the substantial Injection Molding Machine market:

| Market Segment | Value in 2024 (USD) | Projected Value by 2030 (USD) | CAGR (2025-2030) |

|---|---|---|---|

| Plastic Blow Molding Machine | 3.1829 billion | 4.0477 billion | 4.2% |

| Plastic Injection Molding Machine | 11.98 billion | 14.78 billion | 3.5% |

The plastic molding machine market expects a 5.2% CAGR from 2024 to 2032, growing from USD 5.6 billion to USD 8.9 billion. This growth highlights the need for smart equipment choices. Understanding key technical specifications ensures alignment with production goals. The right Injection Moulding Machine Plastic is essential for efficient Plastic Injection Moulding. Businesses also consider Plastic Recycling Machines for comprehensive planning.

Key Takeaways

- Choose the right plastic molding machine type. Electric machines offer precision and save energy. Hydraulic machines provide strong power for big parts. Hybrid machines combine both benefits.

- Understand clamping mechanisms. Two-platen systems save space and fit large molds. Toggle systems are good for fast production. Each system has different benefits.

- Check key technical details. Tie-bar spacing shows the largest mold a machine can hold. Clamping force stops plastic from leaking. Platen size ensures the mold fits correctly.

- Match machine size to your parts. The opening stroke and daylight must be big enough. This helps parts come out easily. A wrong size machine can cause problems and waste.

- Select a machine that fits your project needs. The best machine helps with current work. It also supports future growth. This choice leads to long-term success.

Understanding Fundamental Plastic Molding Machine Types

Choosing the right plastic molding machine starts with knowing the basic types. Each machine offers unique benefits for different production needs. Let’s explore the main categories.

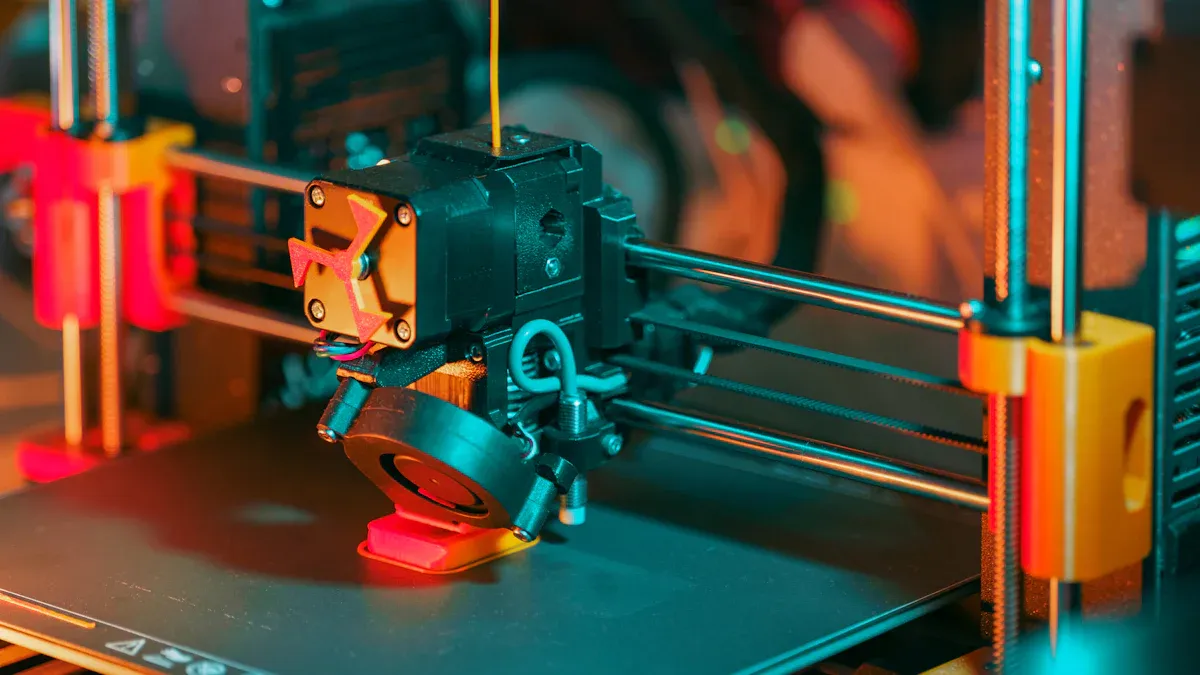

Electric Plastic Molding Machines

Electric plastic molding machines are champions of precision and efficiency. They use electric servo motors for all movements. This design means they only use power when actively working, leading to significant energy savings. For example, these machines can save 50% more energy compared to older hydraulic systems and 20-30% more than servo-hydraulics. Their digital control systems offer incredible accuracy, achieving positioning repeatability of ±0.01 mm. This precision makes them ideal for small, intricate parts and applications needing high consistency. Think about medical devices, electronic components, or optical lenses. These machines excel in cleanroom environments because they do not use hydraulic fluids, preventing contamination.

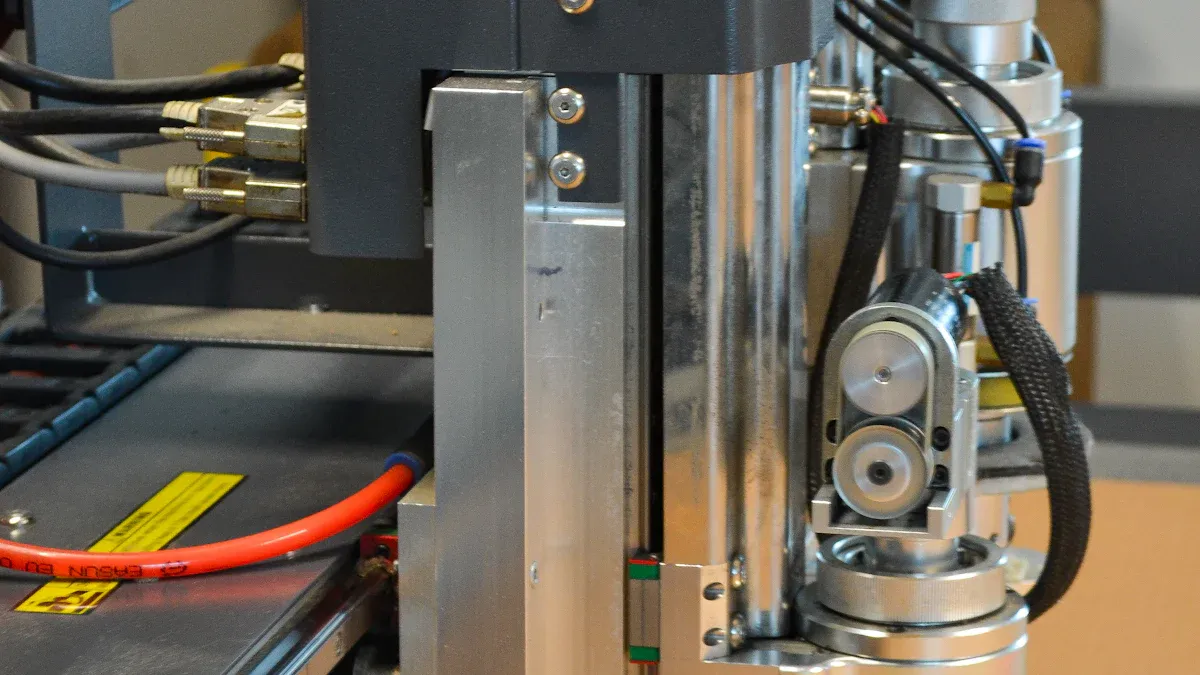

Hydraulic Plastic Molding Machines

Hydraulic plastic molding machines are known for their robust power and durability. They use hydraulic fluid to generate force, especially for clamping. These machines are excellent for high-tonnage applications and molding large, heavy parts with complex details. They can exert immense clamping force, making them perfect for items like automobile bumpers or massive, multi-piece molds. While they might be slower and less precise than electric machines due to fluid dynamics, their strength and versatility in handling diverse materials make them a cost-effective choice for large-scale components in industries like automotive and industrial manufacturing.

Hybrid Plastic Molding Machines

Hybrid plastic molding machines combine the best features of both electric and hydraulic systems. They integrate electric precision with hydraulic power. This means they offer the energy efficiency and accuracy of electric machines, along with the high clamping force and durability of hydraulic ones. Hybrid models are very versatile. They can have hydraulic clamping with electric injection, or vice-versa. This adaptability allows them to handle a broad range of molding tasks, from precise small parts to large, complex components. For instance, they are popular in the automotive industry for dashboard panels and bumpers, and in medical and packaging sectors for their balance of performance and efficiency. These machines can also handle hydraulic functions like core pulls without needing a separate, messy hydraulic unit, which is a big plus for clean environments.

Evaluating Clamping Mechanisms for Plastic Molding Machines

Choosing the right clamping mechanism is a big decision for any plastic molding machine. It directly impacts production efficiency and the types of parts you can make. Quick Mold Change (QMC) systems, for example, are vital for cutting down mold changeover times. These systems can slash downtime from hours to mere minutes. They also boost safety by removing the need for workers to manually attach clamps inside the machine. This means less manual labor and fewer risks.

Two-Platen Clamping Systems

Two-platen clamping systems are known for their compact design. They use two platens to apply force to the mold. This design eliminates the need for a rear clamping platen, giving the machine a much smaller footprint. This is great for manufacturers with limited floor space. These systems also offer flexibility for larger molds. They provide a generous tie bar distance and daylight opening. This allows for multi-cavity tools and complex part geometries. You can mold bigger parts or many smaller parts in one go. Two-platen systems also reduce mold deflection and offer faster cycle times. They are also known for their energy savings.

Toggle Clamping Systems

Toggle clamping systems use mechanical levers and linkages to create clamping force. They are excellent for high-speed injection molding. A toggle unit includes a toggle link, a crosshead, and a driving device. This setup allows for rapid engagement and disengagement, making them perfect for repetitive manufacturing. Toggle clamps offer consistent clamping force. They are designed to “over-clamp,” locking into position without needing continuous hydraulic pressure. This helps maintain force even with manufacturing tolerance issues or vibrations. This system starts with fast, large displacement and low force, then finishes with slow, high force.

However, traditional toggle systems often have a larger footprint due to their inward-moving parts. This can make mold changes less flexible. Outward toggle systems, on the other hand, offer a space-saving design and easier mold access. For maintenance, toggle clamps need regular inspections for wear and damage. You should clean them often and apply lubricant to moving parts. Replacing worn components promptly helps maintain their effectiveness and safety. Their durability depends on the quality of materials and how the linkage system is built.

Key Technical Specifications for Plastic Molding Machine Selection

Choosing the right plastic molding machine means looking closely at its technical details. These specifications tell you what the machine can do and if it fits your project. Understanding them helps you make a smart investment.

Tie-Bar Spacing for Mold Accommodation

Tie-bar spacing is a critical measurement. It tells you the maximum size of a mold a machine can hold. Imagine the tie-bars as pillars holding up the machine’s structure. The mold must fit between these pillars. If a mold is too big for the space between the tie-bars, it simply will not work with that machine. Standard machines often handle molds up to 4 feet by 4 feet. However, larger molds need specialized equipment with wider tie-bar spacing.

Here are some guidelines for fitting molds:

- Mold Dimensions:

- Mold width should be less than half of the horizontal tie-bar spacing.

- Mold length should be less than half of the vertical tie-bar spacing.

- Safety Clearance:

- For small molds, allow at least 25mm of space on each side.

- For large molds, allow at least 50mm of space on each side.

- Mold Thickness: The mold’s thickness must fit within the machine’s minimum and maximum thickness range.

Mold designers also consider these points:

- Mold width or height should be at least 1/2 inch (about 1.27 cm) wider than the cavity size for strength.

- Mold thickness should be 2.5 times the cavity depth to ensure full coverage when closed.

Tonnage Range and Part Size

Clamping force, or tonnage, is how much force the machine uses to keep the mold halves closed during injection. This prevents plastic from leaking out, which people call “flashing.” The clamping force range for machines like Topstar is 90T-2800T. You calculate it based on the part’s projected surface area and the plastic material’s thickness.

Here is how people calculate the required clamping force:

- Rule of Thumb: This method estimates tonnage using the part’s area, plastic type, its thickness, and a ‘clamp factor’ (usually 2 to 8, or an average of 5). However, this can be inaccurate. Too little force causes quality problems, and too much increases mold costs.

- Mold Flow Simulations: These computer programs predict the exact tonnage needed during the design phase. For example, a simulation for one part predicted 509 Tons.

- Theoretical Calculation: You can use a formula: Clamping force (T) = Clamping force constant (Kp) ✕ Projected Area (S in cm²). For instance, if PE plastic has a Kp value of 0.32 and the projected area is 410 cm², the clamping force would be 0.32 ✕ 410 = 131.2 T.

- Mold Filling Analysis: This is a more precise method. It determines the tonnage factor. Adding about a 15 percent safety factor to these results gives very accurate clamping force and prevents flash. This analysis also shows how other factors, like the number of gates (more gates mean lower tonnage) and flow length (longer flow needs higher tonnage), affect the process.

What happens if the clamping force is wrong?

| Aspect | Insufficient Clamping Force | Excessive Clamping Force |

|---|---|---|

| Part Quality | Flash, poor symmetry, short shots, inaccurate dimensions, weak weld lines | No flash, but overpacking causes internal stress or sink marks; mold deflection, part sticking, or surface blemishes |

| Mold & Machine Impact | Mold wear at parting lines from repeated flashing; uneven clamping damages pins/bushings | Premature mold damage (cracks, wear on guide pins/platens); deformed platens, cracked inserts |

| Production Costs | More scrap, rework, and downtime for mold cleaning | Higher maintenance costs and risk of machine breakdowns |

| Energy Efficiency | Minimal energy waste, but high scrap rates | Unnecessary energy consumption from machine overloading |

| Cycle Time | Longer cycles to fix defects (like removing flash) | No improvement in cycle time; potential delays from mold damage |

Insufficient clamping tonnage wears out molds faster. Uneven clamping can damage leader pins and bushings. This means more downtime and higher maintenance costs. Excessive clamping tonnage can cause burn marks on parts because air cannot escape. It also increases internal mold pressure, making the injection process inconsistent.

Platen Size and Layout for Mold Fit

Platen size and layout are like a gatekeeper for mold compatibility. The mold must fit within the machine’s platens. Its width and height, including mounting plates, must be smaller than the space between the machine’s tie bars. If a mold is even a little too wide, it simply will not fit. A mold designed for a larger machine (like a 500-ton) cannot physically fit or work on a smaller one (like a 200-ton).

Consider how the part design affects the mold layout:

- A larger preform neck diameter needs more space between cavities on the mold plate. This increases the overall mold base size.

- For a fixed platen size, a 28mm PCO1881 neck (common for water bottles) might allow a 50mm pitch. This could mean an 8×9 layout for a 72-cavity mold.

- However, a 38mm Bericap neck (for juices) might need a 70mm pitch for its larger diameter. This could reduce the layout to 6×6, resulting in only a 36-cavity mold within the same physical area.

This shows that a wider neck size forces a larger mold base for the same number of cavities. This ultimately means a lower maximum number of cavities for a given plastic molding machine.

Platen parallelism and rigidity are also very important. They ensure consistent part quality. Intelligent leveling systems and precise platen control help keep the platens perfectly flat and parallel. This prevents defects from uneven clamping pressure. Surface milling creates flat, parallel surfaces on mold base plates within tight tolerances, often 0.005mm per 100mm of length.

Opening Stroke and Daylight for Ejection Efficiency

The opening stroke and daylight are crucial measurements for any plastic molding machine. They directly affect how easily and efficiently a molded part comes out of the mold. The opening stroke refers to the distance the moving platen travels. Daylight is the maximum open space between the mold halves when the machine is fully open. Both must be large enough for the part to clear the mold without issues.

If the open space, or daylight, between the mold halves is not enough for the part to eject properly, it creates several problems. Manufacturers might need a larger, more expensive machine with a greater opening stroke. This can lead to various inefficiencies:

- Material degradation happens because plastic stays in the barrel longer.

- Mold wear increases due to higher clamping pressures.

- Component flashing occurs when platens rock because a smaller mold is in a large machine.

- Shot inconsistency results when a large injection unit delivers a small shot volume.

- Cycle times increase because larger machines typically operate slower.

The ejection stroke is also very important. This is the distance the ejector pins push the part out of the mold. The required ejection stroke must fit within the machine’s capabilities. Parts with a greater draw depth, like tubes or deep containers, need longer ejection strokes for proper removal. The ejector cylinder’s length determines the maximum available ejection stroke. Mold designers always verify this if they have doubts about its sufficiency. They ensure the machine can push the part out completely and cleanly.

Selecting a Plastic Molding Machine is an ongoing process. It matches project needs with machine specifications. The best machine aligns with current production demands and supports future expansion. Strategic investment in the right machine is paramount for long-term operational success and profitability. This includes embracing lean manufacturing principles to cut waste and leveraging digital manufacturing for real-time monitoring. Companies also diversify their customer base and invest in a skilled workforce. These steps ensure sustained growth and efficiency.

FAQ

What is the main difference between electric and hydraulic plastic molding machines?

Electric machines offer precision and energy savings. They use servo motors for all movements. Hydraulic machines provide robust power for large parts. They use fluid pressure. Hybrid machines combine both benefits, offering versatility.

Why is tie-bar spacing important for machine selection?

Tie-bar spacing determines the maximum mold size a machine can hold. The mold must fit between these pillars. Incorrect spacing means the mold will not work with that machine. It is a critical measurement for mold accommodation.

How does clamping force affect the quality of molded parts?

Clamping force keeps mold halves closed during injection. Too little force causes “flashing” or poor part quality. Too much force can damage the mold or cause part defects like sink marks. Proper clamping ensures consistent results.

What are the benefits of a two-platen clamping system?

Two-platen systems offer a compact design, saving floor space. They provide generous tie-bar distance and daylight opening for larger molds. These systems also reduce mold deflection and can lead to faster cycle times.

When should a business consider a hybrid plastic molding machine?

Businesses should consider hybrid machines when they need both precision and power. These machines combine electric accuracy with hydraulic strength. They are versatile, handling a broad range of molding tasks efficiently.