Granulator Machine Brands Compared Key Differences Explained

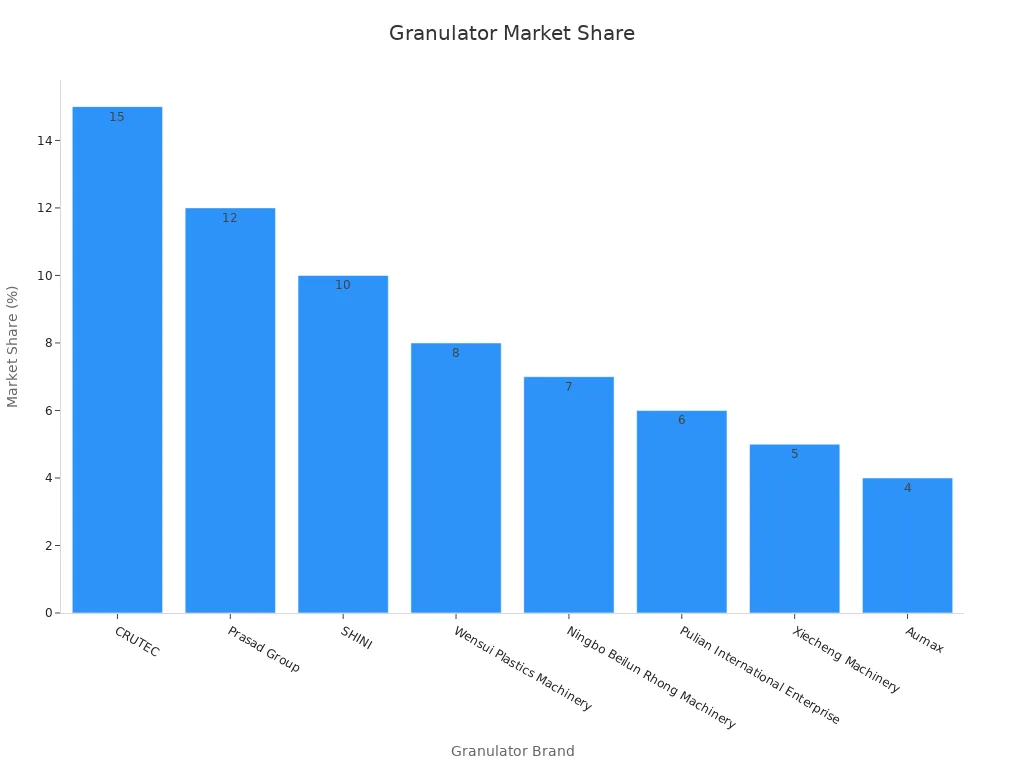

Choosing the right granulator machine shapes how a factory runs every day. Brands stand apart because of their performance, capacity, and how well they handle different materials. For example, the market for fertilizer granulators is growing fast, as shown below:

| Metric | Value (2023) | Projected Value (2032) | CAGR (%) |

|---|---|---|---|

| Market Size (USD) | 1.5 billion | 2.6 billion | 6.2 |

Plastic granulator makers use new technology to boost efficiency and cut costs. Many factories now use low speed granulators for quieter, safer work. Some brands offer strong after-sales support, while others focus on keeping operating costs low.

A plastic pelletizer with smart features can help companies save money and reduce downtime. These differences mean every production line needs to pick the best fit.

Key Takeaways

- Choosing the right granulator machine brand helps factories save money, reduce downtime, and improve production quality.

- Performance, capacity, and material compatibility are key factors to match a machine to your specific production needs.

- Modern granulators use smart technology and automation to boost efficiency, ensure consistent output, and lower labor costs.

- Easy maintenance, durable parts, and strong after-sales support reduce stress and keep machines running longer.

- Consider both upfront cost and long-term value, including energy use and warranty, to get the best return on investment.

Granulator Machine Side-by-Side Brand Comparison

Top Granulator Machine Brands Overview

When people look for a granulator machine, they often start by checking out the top brands. Each brand brings something different to the table. For example, Cumberland stands out for high performance and less maintenance. Granutec offers custom engineering and durability. Shini USA is known for quality and support, while Rapid focuses on modern design and sustainability. Zerma America has over 70 years of experience and provides comprehensive solutions. Some brands, like Glatt and GlobePharma, lead in new technologies and global service. Others, such as WITTMANN and WEIMA, focus on energy savings and user-friendly designs.

Tip: Choosing the right brand can help factories save money and reduce downtime.

Comparison Table: Key Specs and Features

Here’s a quick look at how some leading brands compare on important features:

| Brand | Power (KW) | Capacity (ml/h) | Key Features | Noted Weaknesses |

|---|---|---|---|---|

| Cumberland | 5 | 1500 | High performance, less maintenance | High initial investment |

| Granutec | 5 | 1500 | Custom engineered, durable | Limited technical details |

| Shini USA | 5 | 1500 | Quality, cost-effective, good support | Potential maintenance issues |

| Rapid | 5 | 1500 | Compact, modern, sustainable | High initial cost |

| Zerma America | 5 | 1500 | Comprehensive solutions, experience | Material limitations |

Most granulator machines use stainless steel and have a 7-inch LCD display for easy operation. They handle a wide range of materials, including sugary and heat-sensitive ones. Many models combine spray granulation, drying, and coating in one unit. Users can choose from different nozzle sizes and granulation techniques, such as pneumatic dry or fluidized bed granulation. Bulk density and particle size also affect how each machine works.

Granulator machines come in different scales, from 1 liter to 50 liters. No matter the size, machines with constant tip speed usually produce granules with similar strength. However, machines using constant shear stress may create weaker granules at smaller scales.

Granulator Machine Key Comparison Factors

Performance and Output Quality

Performance and output quality set the foundation for any granulator machine. When factories look for the best fit, they often start by asking, “How well does this machine do its job?” Several factors shape the answer:

- Screen size in plastic granulators controls the size and uniformity of the particles. Smaller screens create finer, more even granules, but they slow down the process and can make more dust. Larger screens speed things up but produce bigger, less uniform pieces.

- Too many fines, or tiny particles, can cause problems. They may lead to material loss or even safety hazards in the workplace.

- The right screen size balances the need for small, uniform granules with the need for speed and safety.

- Sharp knives and smart machine design also help improve output quality and save energy.

Different industries have their own needs. The pharmaceutical industry, for example, demands very uniform granules to meet strict rules and make sure medicines work as they should. Chemical and fertilizer makers want machines that can handle big jobs while keeping quality steady. Companies now invest in smart controls and automation to boost performance and keep output consistent. New machines, like those with advanced software, show how much the industry values steady, high-quality results.

Note: Choosing a granulator with the right screen and sharp blades can make a big difference in both quality and efficiency.

Capacity and Throughput

Capacity and throughput tell you how much work a granulator machine can handle. These numbers matter for any business that wants to keep up with demand and control costs. Reports show that new rotor designs and better energy use help machines work faster and need less fixing. Open rotor granulators, for example, are easy to maintain and can handle more material at once.

Modern factories use sensors to track how much material goes through the machine each day. They watch for slowdowns and plan maintenance before problems start. This real-time tracking helps companies get the most out of their machines and avoid costly downtime.

Efficiency means turning raw materials into granules quickly and with little waste. Production capacity is the total amount of granules made in a set time. A machine with high capacity but low efficiency can actually slow things down and raise costs. Buyers should look for a balance between these two numbers to get the best results.

Material Compatibility

Material compatibility is a must-have feature for any granulator machine. Factories work with many types of materials, from plastics and chemicals to new, eco-friendly options. The right machine handles all these without breaking down or ruining the product.

- Efficiency and production capacity depend on how well the machine works with different materials.

- Machines must handle new, sustainable materials as well as traditional ones.

- If a machine cannot process a certain material, it can lead to product loss or even damage the equipment.

Maintenance and durability also play a role here. A machine that is easy to clean and tough enough for many materials will last longer and cost less over time. User feedback often highlights how well a machine handles different materials, which helps buyers make smart choices.

Tip: Always check if the granulator machine can handle your main materials before buying. This step saves time and money in the long run.

Technology and Automation

Technology keeps changing how factories use granulator machines. Many companies now add smart controls and automation to their equipment. These upgrades help workers do less manual work and make the machines run better.

- Automation and IoT (Internet of Things) let operators watch the machine in real time. They can see if something goes wrong and fix it fast.

- Smart granulators use sensors to control temperature and moisture. This helps make granules that are always the same size and quality.

- New machines save energy and use eco-friendly materials. This helps companies meet green goals and lower their bills.

- Factories can now change settings quickly to make different products. This makes the machines more useful for many jobs.

Recent surveys show that these changes help companies in many ways:

- Productivity goes up because machines work faster and need fewer breaks.

- Precision improves, so there is less waste and better product quality.

- Labor costs go down since fewer people need to watch the machines.

- Companies in North America and Europe lead in using these new technologies, but Asia-Pacific is catching up fast.

Note: Some companies worry about the high cost of new technology and the need for special training. Still, most find that the benefits are worth it.

Maintenance and Durability

Keeping a granulator machine running well takes regular care. Some brands make this easier than others. Machines with simple designs and easy-to-reach parts save time during cleaning and repairs. Open rotor designs, for example, let workers get inside the machine quickly to fix problems.

Durability matters, too. A tough machine can handle many types of materials without breaking down. Stainless steel parts last longer and resist rust. Some brands use extra-strong blades that stay sharp for a long time. This means less downtime and lower repair costs.

- Regular maintenance checks help spot small issues before they become big problems.

- Machines with smart sensors can warn workers when something needs fixing.

- Companies that offer good after-sales support make it easier to keep machines in top shape.

Tip: Choosing a machine that is easy to maintain can save money and reduce stress for workers.

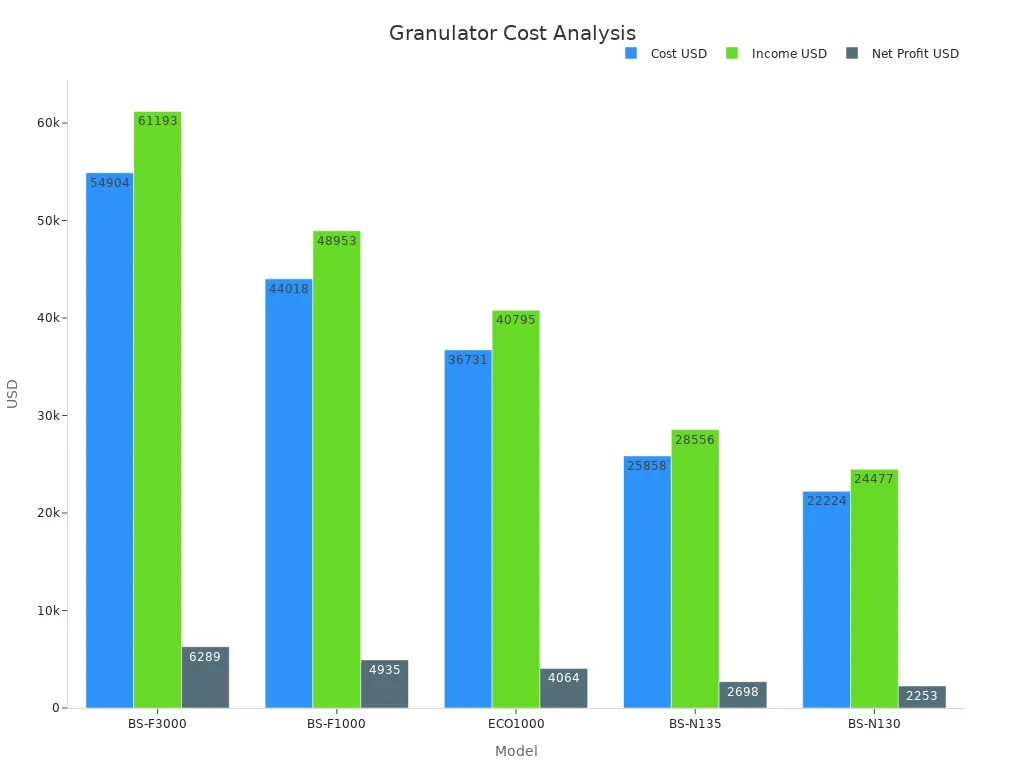

Cost and Value for Money

Buying a granulator machine is a big decision. The price can change a lot based on the brand, size, and features. Some machines cost more at first but save money over time because they use less energy and last longer.

Here is a table that compares the cost, power use, and profit for different models:

| Model | Power Consumption (KW/H*8H) | Cost (USD) | Income (USD) | Net Profit (USD) |

|---|---|---|---|---|

| BS-F3000 | 120 | 54,904 | 61,193 | 6,289 |

| BS-F1000 | 108 | 44,018 | 48,953 | 4,935 |

| ECO1000 | 76 | 36,731 | 40,795 | 4,064 |

| BS-N135 | 75 | 25,858 | 28,556 | 2,698 |

| BS-N130 | 67 | 22,224 | 24,477 | 2,253 |

The table and chart show that higher-priced models like BS-F3000 and BS-F1000 can make more profit in the long run. Lower-cost models, such as BS-N135 and BS-N130, cost less to buy and run, so they pay for themselves faster.

Some brands, like Wintech, offer modular designs that keep costs low. Others, like US brands, may cost more but give better control and precision. It is important to match the machine to your needs and budget. Adding extra equipment can also increase the value you get from your purchase.

Tip: Think about both the upfront cost and the long-term savings when choosing a granulator machine.

After-Sales Support and Warranty

After-sales support and warranty can make or break a buyer’s experience with a granulator machine. When a factory buys new equipment, they want to know help is there if something goes wrong. Good support means less downtime and fewer headaches.

Most top brands offer some kind of warranty. The length and coverage can vary a lot. Some companies give a one-year warranty. Others might offer two or even three years. A longer warranty often shows the brand trusts its own product.

Here’s what buyers should look for when comparing after-sales support and warranty:

- Warranty Length: Longer coverage gives peace of mind. It protects against early breakdowns.

- Parts Availability: Fast access to spare parts keeps the line running. Some brands keep parts in stock locally. Others ship from overseas, which can take longer.

- Technical Support: Many brands offer phone or online help. Some even send technicians to the site. Quick answers help solve problems before they get big.

- Training: Good brands teach workers how to use and maintain the machine. This training can prevent mistakes and extend the life of the equipment.

- Service Contracts: Some companies sell extra service plans. These plans cover regular check-ups and repairs.

Tip: Always ask about support before buying. A cheap machine with poor support can cost more in the long run.

Let’s see how some leading brands stack up:

| Brand | Warranty Length | Local Parts Stock | On-Site Service | Training Provided |

|---|---|---|---|---|

| Cumberland | 2 years | Yes | Yes | Yes |

| Granutec | 1 year | Yes | Yes | Yes |

| Wintech | 1 year | Limited | No | Yes |

| Rapid | 2 years | Yes | Yes | Yes |

| Shini | 1 year | Yes | Yes | Yes |

| Zerma | 2 years | Yes | Yes | Yes |

| Piovan | 2 years | Yes | Yes | Yes |

Some brands, like Cumberland and Rapid, stand out for their longer warranties and strong local support. Wintech offers good training but has fewer local parts. Brands with global service networks, such as Piovan, can help buyers in many countries.

A factory manager should always check the details. Does the warranty cover just parts, or does it include labor? Are there extra costs for on-site visits? Reading the fine print helps avoid surprises.

Note: A reliable after-sales team can turn a small problem into a quick fix instead of a costly shutdown.

Choosing a granulator machine is not just about specs and price. After-sales support and warranty play a big role in keeping production smooth and stress-free.

Pros and Cons of Each Granulator Machine Brand

Cumberland: Strengths and Weaknesses

Cumberland stands out in the granulator world. Many factories trust this brand for its strong build and reliable performance. Cumberland machines handle high volumes with ease. They often run for long hours without breaking down. This makes them a favorite for busy production lines.

Strengths:

- High capacity and throughput

- Durable construction with quality materials

- Easy access for maintenance

- Strong after-sales support and long warranty

Weaknesses:

- Higher upfront cost than some competitors

- Large size may not fit smaller spaces

- Advanced features can require extra training

Cumberland works best for companies that need power and reliability every day.

Granutec: Strengths and Weaknesses

Granutec offers custom solutions for many industries. Their machines focus on durability and flexibility. Many users like the way Granutec can tailor machines to fit special needs. The brand also gets good marks for its support team.

Strengths:

- Custom engineering for unique applications

- Solid build quality

- Good technical support and training

- Handles a wide range of materials

Weaknesses:

- Limited technical details available before purchase

- May have longer lead times for custom orders

- Not always the most energy-efficient option

Granutec fits companies looking for a machine built just for them.

Wintech: Strengths and Weaknesses

Wintech granulators help factories cut costs and stay competitive. They work well with other equipment, making it easy to recycle trimmings and reduce waste. Many businesses choose Wintech for its value and focus on quality.

- Wintech granulator machines are part of a larger product line.

- The company shares case studies and quality management info.

- They focus on after-sales service and product quality.

Strengths:

- Helps lower production costs by recycling materials

- Good cost-performance ratio

- Strong focus on quality and customer service

Weaknesses:

- No detailed performance metrics available

- Limited local parts stock in some regions

- Fewer advanced features than premium brands

Wintech suits buyers who want solid value and easy integration with other machines.

Rapid Granulator: Strengths and Weaknesses

Rapid Granulator stands out for its focus on research and smart design. The company does not just follow old standards. For example, after 18 months of research, Rapid found that running the impeller at 15 rpm works better than the old 25 rpm standard. This led to the OneCut Pro series, which shows how Rapid uses real data to improve machines.

Many users like Rapid’s advanced features. The machines have optimized impeller and chopper designs. They use PLC control systems with Siemens panels. Operators can scale production and keep quality steady. Rapid machines work well for many products, including pharmaceuticals and chemicals. Safety is a big deal, too. The machines have enclosed drives, emergency stops, and alarms.

| Strengths | Weaknesses |

|---|---|

| Research-driven innovation | Can be complex to operate |

| Advanced automation | Higher upfront cost |

| Strong safety features | Needs careful operator training |

| Versatile for many uses | Some process steps need tweaking |

Users say Rapid machines give predictable results and keep workers safe. Some people find the controls complex at first. They also note that scaling up production can take some trial and error. Rapid’s focus on quality and safety makes it a top choice for companies that want the latest technology.

Tip: Rapid Granulator works best for factories that want control, safety, and modern features.

Shini: Strengths and Weaknesses

Shini offers granulator machines that balance quality and price. Many factories pick Shini because the machines are easy to use and maintain. Shini’s support team helps buyers set up and run their machines. The company also provides training for workers.

Strengths:

- Good value for the price

- Simple controls and easy maintenance

- Reliable customer support

- Works well for small and medium factories

Weaknesses:

- May not have the most advanced features

- Some users report minor maintenance issues

- Limited options for large-scale production

Shini machines fit companies that want a solid, no-fuss solution. They may not have all the bells and whistles, but they get the job done without much trouble.

Note: Shini is a smart pick for buyers who want reliability without a high price tag.

Zerma: Strengths and Weaknesses

Zerma has a strong reputation in the plastic recycling world. Industry reports highlight Zerma’s robust design and long-lasting machines. Many companies trust Zerma for heavy-duty jobs, especially when dealing with tough plastic waste.

- Zerma machines handle industrial plastic waste with ease.

- The brand stands out for durability and solid construction.

- Reports show Zerma’s focus on new product launches and global reach.

- Product benchmarking points to Zerma’s strength in industrial settings.

| Strengths | Weaknesses |

|---|---|

| Very durable build | Detailed technical comparisons not always available |

| Handles tough materials | May require paid reports for deep data |

| Good for heavy industry | Fewer options for small-scale use |

Zerma suits factories that need a tough, reliable machine for big jobs. The brand’s focus on durability means less downtime and fewer repairs.

Tip: Zerma is a top choice for heavy-duty recycling and companies that want machines built to last.

Piovan: Strengths and Weaknesses

Piovan stands out as a major player in the global granulator market. Many factories choose Piovan because the company invests heavily in research and development. This focus on innovation helps Piovan keep up with changing industry needs. The Granulators Market report lists Piovan alongside other top brands like Conair Group, Rapid Granulator AB, and Cumberland. This recognition shows that Piovan has strong technological capabilities and a solid market presence.

Piovan granulators use advanced design features that help factories work smarter. The machines use a special “Scissor” cutting action. This design reduces energy use, heat, and dust. Workers notice that Piovan machines run quietly and need less cleaning. The company offers models for many jobs, from small batches up to heavy-duty work. Some machines handle up to 5,000 kilograms per hour. Others work well for smaller tasks.

Here are some key strengths of Piovan granulators:

- Advanced “Scissor” cutting action lowers energy costs and dust.

- Wide range of models for different production needs.

- Low noise levels make the workplace safer and more comfortable.

- Easy maintenance with quick blade replacement and accessible parts.

- High wear resistance means longer machine life.

- Extra systems like air filtering and de-dusting keep the area clean.

Still, Piovan machines have some weaknesses. The advanced features can make the machines more expensive than basic models. Some users say the technology requires extra training for workers. Heavy-duty models may take up more space on the factory floor.

Tip: Piovan works best for companies that want high-tech solutions and care about energy savings and clean workspaces.

Real-World Granulator Machine User Feedback

User Reviews and Ratings

People who use granulator machines every day have strong opinions about what works and what does not. Many operators say that machines with easy-to-use controls make their jobs much simpler. They like when the display shows clear numbers and warnings. Some users mention that machines with smart sensors help them spot problems before they get worse. This feature saves time and keeps the production line moving.

A lot of reviews praise brands that offer quick support and fast parts delivery. Workers feel less stressed when they know help is just a call away. Some users point out that machines with simple designs are easier to clean and fix. They do not need to stop production for long. Others mention that quieter machines make the workplace safer and more comfortable.

Note: Users often give higher ratings to machines that run smoothly and need little maintenance. They also value brands that listen to feedback and keep improving their products.

Case Examples from Different Industries

Granulator machines play a big role in many industries. Companies in pharmaceuticals, plastics, and chemicals all use these machines to get the right particle size and quality. Here are some real-world examples:

- In oral solid dose (OSD) manufacturing, companies use granulators for both batch and continuous systems. They use NIR spectroscopy to check particle size and spot inconsistencies. This helps them catch problems that old tests might miss, like changes in median size or too many fines. These checks improve blending and compression quality.

- Some factories use twin-screw granulation (TSG) with advanced computer models. These models predict how granules will form and grow. They use tools like Discrete Element Method (DEM) and Population Balance Modeling (PBM) to get accurate results. NIR and Raman spectroscopy help confirm the predictions.

- One team built a data-driven model for twin-screw granulation. Their system predicts granule size with high accuracy and adjusts settings in real time. This keeps the process steady, even when something changes suddenly.

These examples show that real-time monitoring and smart controls help companies make better products. They also show how different industries use both hands-on experience and advanced technology to get the best results from their granulator machines.

Choosing the right Granulator Machine depends on what a company needs most. Some brands work better for high-volume jobs, while others shine with smart technology or lower costs. The table below shows what shapes these choices for 2025:

| Key Factor Category | Details and Influence on Brand Choice for 2025 |

|---|---|

| Growth Drivers | Expansion of pharmaceutical and nutraceutical sectors; increasing demand for efficient dry granulation processes. |

| Regional Market Dynamics | North America and Europe hold significant shares with established manufacturers; Asia-Pacific shows rapid growth and adoption. |

| Technological Advancements | Automation, Industry 4.0 integration, advanced roller compaction, improved material handling enhancing efficiency and quality. |

| Regulatory Compliance | Strict GMP and safety standards require machines with robust quality control, influencing brand preference. |

| Sustainability Trends | Increasing focus on eco-friendly designs and energy-efficient machines shaping brand innovation and selection. |

Cumberland stands out for big jobs. Rapid Granulator and Piovan lead with automation. Wintech helps buyers save money. Companies should look at their own needs and match them to the right brand.

Companies see more demand for automation, safety, and eco-friendly features. Smart monitoring and regional trends also shape which brand fits best.

FAQ

What materials can most granulator machines handle?

Most granulator machines work with plastics, chemicals, and some food products. Some models process eco-friendly or heat-sensitive materials. Always check the machine’s specs before buying. Each brand lists compatible materials in its manual or on its website.

How often should operators perform maintenance on a granulator machine?

Operators should check and clean the machine after each use. Most brands recommend a full inspection every month. Regular maintenance keeps the machine running smoothly and helps prevent breakdowns.

Do all granulator machines come with a warranty?

Yes, all major brands offer a warranty. The length and coverage can vary. Some brands provide one year, while others offer up to three years. Always read the warranty details before making a purchase.

Can one person operate a granulator machine safely?

Yes, one trained person can operate most granulator machines. Safety features like emergency stops and clear controls help. Operators should always follow the brand’s safety guidelines and wear protective gear.